National Ladder Safety Month: Innovative Product Design

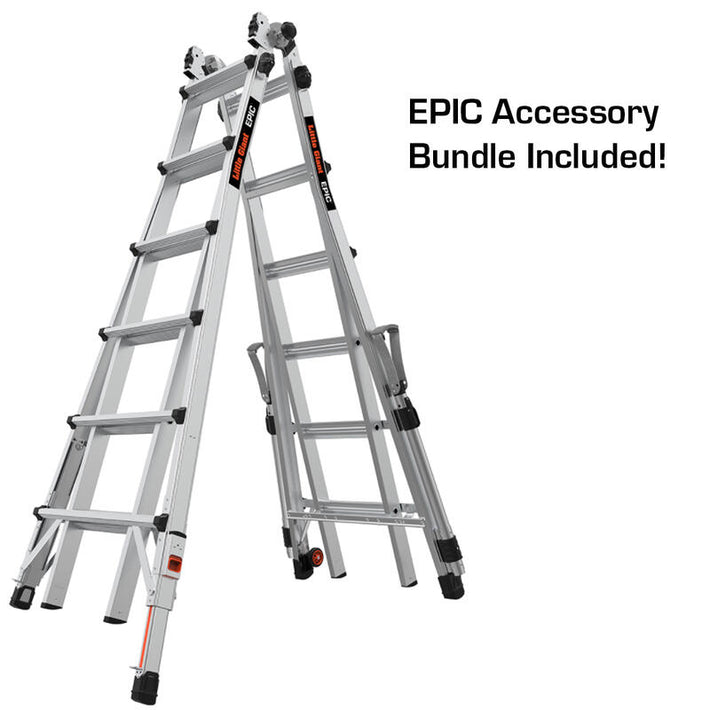

Welcome to week 3 of National Ladder Safety Month. Last week we discussed ladder accident statistics and trends. This week, we’ll be going over how to convert those numbers into intuitive products. We’ll even take a look at some examples from Little Giant’s catalog.

Going from Research to Rivets

Let’s revisit a study we touched on earlier in Ladder Safety Month: a Harvard School of Public Health report that surveyed 254 ladder fall victims across 65 US hospitals. The report had a few interesting statistics, including a pie chart with the most common mechanisms leading to ladder falls. “Ladder Moved” takes the lion’s share with 40%.

You can see there are a number of ways the ladder can move to cause an accident. If you’re an experienced climber, or just plain clever, you’ll notice that the most common causes are rooted in user error rather than a ladder malfunction: sideways falls (9%) typically occur when overreaching, and bottom or “slip out” falls (25%) typically occur because the angle of the ladder was set incorrectly. Exceptions to the rule could be using a ladder with worn or damaged feet, but again, the problem is a matter of inspection and maintenance—a user action.

So, if the most frequent accident type is commonly caused by the user, not the product, how can a manufacturer make a difference?

The obvious answer is training, but we’ll get back to that in a minute. The less obvious answer is intuitive design. Let’s take a look at two products that illustrate this principle: the King Kombo® and the SumoStance®.

The 4-to-1 ratio is OSHA’s approved angle for portable, leaning ladders: one foot from the wall for every four feet of ladder height. There are professional checks for this, such as the arm-to-rung test, but users without training naturally set a shallow angle. The King Kombo’s non-slip, treaded feet are actually angled so they stand flat when the ladder is leaning at the correct ratio, meaning users can physically see their shallow angle as an abnormal gap beneath the feet. The ladder was designed with intuitive visual cues.

The SumoStance, on the other hand, has articulating feet on leveling outriggers for outdoor use. At 16+ feet tall, every degree away from a level base means a significant lean at the top. So, both the lean angle and side-tip angle are shown on bubble levels attached to the side of the ladder and the bottom rung. The ladder was designed with intuitive tool synergies.

Qualitative Beta Testing

Of course, quantitative data can only get us so far, since we have to make assumptions about the actual behavior behind the numbers. Qualitative data, on the other hand, gives us a direct glimpse into the actions of our users.

For example, the second most common ladder accident from our Harvard study is “Foot Miss/Slip” at 24%. But that could mean a number of missteps: an accidental upwards overstep, a missed downward step, a literal slip on the rung, a jammed toe on jutting steps, a rolled ankle on harness rope, a hyperextended knee from skipping the bottom step, etc. Plus, CDC data on the height of ladder accidents found that 50% occur below 10 feet, which is a useful statistic until you want to know exactly what step people are missing.

That’s why, long before any Little Giant product makes it to market, our ladders and accessories undergo a stringent beta testing period. Industry professionals and DIYers put our prototypes to work, then report back on what went well and what didn’t. We compile the data and compare it with resources like the American Ladder Institute’s (ALI) survey-based safety reports.

Let’s look at the King Kombo again and one of the features that came from this process:

When our beta testers said the same thing as ALI’s reports, we knew we were onto something. A majority of users (upwards of 35%) were reporting missing the last step of the ladder on the way down—in other words, they were assuming the ground was closer than it actually was.

Enter the Ground Cue®. We call it ankle insurance: a weight-activated step that makes an audible and tactile “click,” letting you know you’ve reached the bottom of the ladder. This innovation came directly from a qualitative understanding of ladder accident data.

Honorable Mentions

Of course, we couldn’t hit everything, so here are a few quick intros to additional product innovations that are driving intuitive safety.

Rotating Wall Pad: Whether you’re a framer, a roofer or an electrician, working around studs and on corners is pretty much part of the job description. The King Kombo and Sentinel™ both come with rotating wall pads that lean on inside and outside corners, 2x4 studs and walls.

Cable Hooks: Leaning a ladder on a telephone cable is tricky business—especially when that cable is angled. The HyperLite’s™ cable hooks latch onto the line while keeping the ladder level to prevent pinwheeling.

Comfort Steps: Standing on three inches of aluminum is simple enough. Doing it for hours? Not so much. When you’re ten feet up for most of your day—like our drywallers—every inch of step matters. So, the Sentinel has six-inch steps at the top instead of three.

Safety Cage: With a wraparound rail and toe kick, the Safety Cage 2.0 eliminates industrial tie-off requirements while still allowing 360° of work freedom.

Fuel Tank & Cargo Hold: Remember those stats about holding tools while climbing? The Fuel Tank gives painters an attachable paint tray that stays at the top, and the Cargo Hold gets tools out of your hands and into the air.

But What About Training?

Helping the user understand safe best practices through labeling, instructional materials and video demonstrations is also an incredibly important method of reducing accidents. But we’ll save that discussion for next week!

If you’d like to see how Little Giant began offering free, certified OSHA training across the US, join us for week 4 of Ladder Safety Month. We’ll take a look at why Little Giant built three fully staffed broadcasting studios and launched a global training campaign.

***

2022 National Ladder Safety Month:

- Week One – Introduction to Little Giant’s New Safety Goal

- Week Two – Ladder Accident Statistics and Trends

- Week Three – Safety Solutions Through Innovative Product Design

- Week Four – LIVE Education Through Broadcast Training

Additional Resources:

- Facebook: www.facebook.com/LittleGiantLadders

- Twitter: https://twitter.com/littlegiant

- Instagram: https://www.instagram.com/littlegiantladders/

For more information contact:

Email: pr@ladders.com